Service and Maintenance

Cabin and Machinery Servicing, Gas Burner Servicing, Breathable Air Testing. Available for all spray booth brands Australia wide - Melbourne, Sydney, Perth, Brisbane.

Prevent It Maintenance Program by Total Spraybooth Care

Total Spraybooth Care (TSC) offers the Prevent It Maintenance Program, designed to ensure that your spray booth operates safely, efficiently, and in compliance with regulations.

Regular maintenance is critical for maintaining insurance coverage and reducing the risks of fire, injury, and costly downtime. The Prevent It program focuses on preventing issues before they escalate, keeping your equipment in optimal condition.

What is Prevent It?

The Importance of Servicing Your Spray Booth

Proper servicing not only ensures that your spray booth runs smoothly but also significantly lowers risks and operational costs:

- Fire Prevention: Regular maintenance helps reduce the buildup of paint dust and overspray, which are key fire hazards in spray booths.

- Safety for Workers: Preventative care minimizes the risk of injury by ensuring the booth functions correctly and safely, protecting workers from harmful fumes and unsafe conditions.

- Reducing Downtime: Unplanned breakdowns lead to costly downtime. Regular checks ensure potential issues are addressed early, allowing for smooth, continuous operation.

- Cost Efficiency: Maintenance can help detect air leaks that drive up the cost of compressed air. Keeping your ventilation systems in check ensures that airflow is adequate and energy-efficient, saving on utility costs

Qualified Technicians

- Licensed Electricians ensure that all electrical components, from control systems to lighting, meet safety and operational standards.

- Licensed Gasfitters inspect and service gas connections and systems, ensuring compliance with Australian gas safety regulations.

- Licensed Type-B Gasfitters handle more complex gas installations, including those specific to spray booth heating systems.

Types of Servicing

Cabin and Machinery Servicing

This includes cleaning fans, replacing worn seals, lubricating pivot points, and readjusting sensors. Regular cleaning and maintenance of machinery ensure that equipment operates smoothly, preventing mechanical issues before they become major problems.

Gas Burner Servicing

The heating system is one of the most critical parts of a spray booth. Without proper curing, the spray booth cannot function effectively, making this aspect of maintenance vital. Regular servicing of the gas burner ensures that the heating system is safe, efficient, and compliant with relevant gas safety standards.

Breathable Air Testing

Legal Obligations and Regulatory Compliance

Insurance

What Happens Without Regular Servicing?

Neglecting maintenance can lead to severe consequences:

- Increased Fire Risk: Buildup of overspray and dust can cause fires.

- Higher Injury Risk: Faulty or poorly maintained equipment puts workers at risk.

- Unplanned Downtime: Breakdowns due to neglect can cause delays, reducing productivity and increasing costs.

- Increased Operational Costs: Energy efficiency drops, and the cost of repairs increases the longer issues are left unaddressed.

- Non-Compliance with Legal Standards: Failing to meet legal requirements could result in penalties and loss of insurance coverage.

Regular servicing through the Prevent It Maintenance Program ensures that your spray booth operates smoothly, safely, and within regulatory frameworks. By staying proactive, you can minimize risks, costs, and downtime, ensuring that your spray booth remains in top condition for years to come.

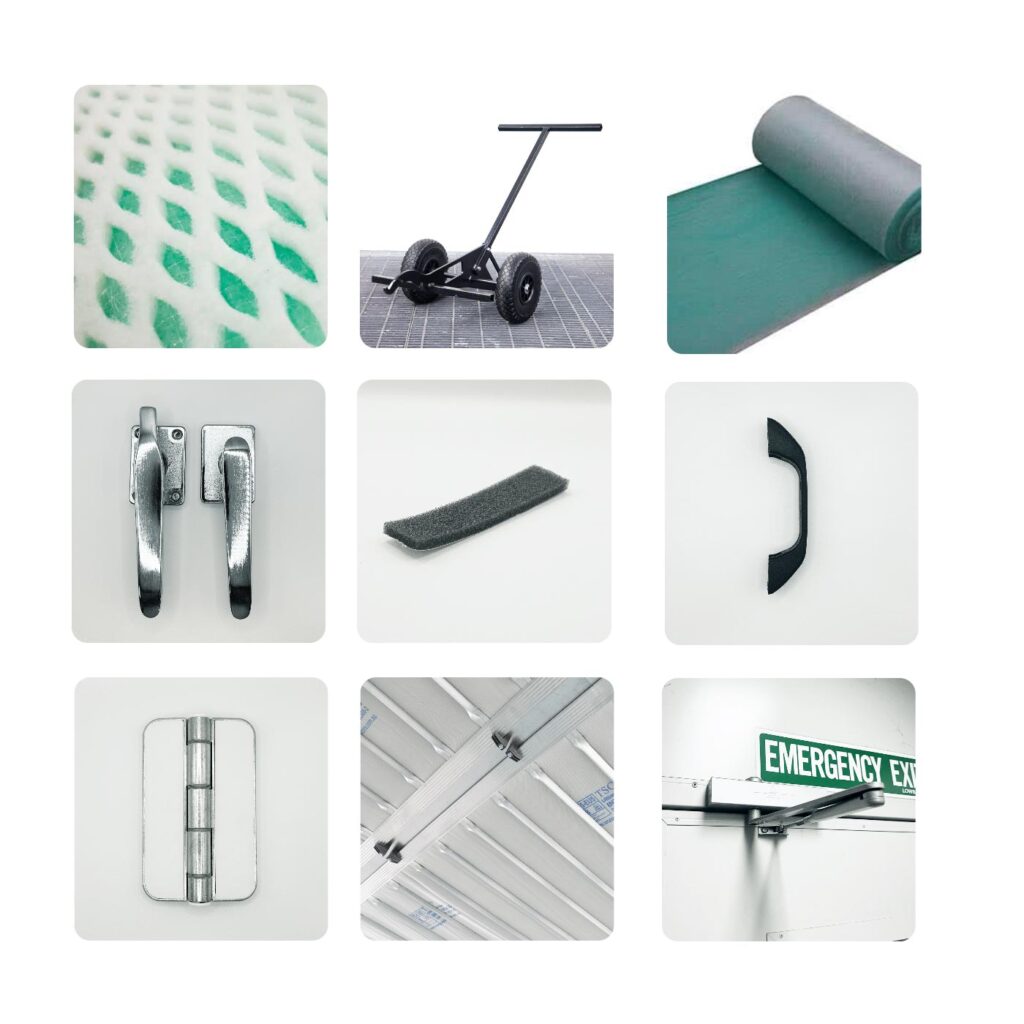

Looking for filters and parts? Our online shop stocks a complete range of spray booth filters, door consumables, cabin consumables, and vacuum parts to keep your spray booth running at peak performance. From roof inlet filters to floor exhaust filters, every product meets high industry standards for durability and efficiency.